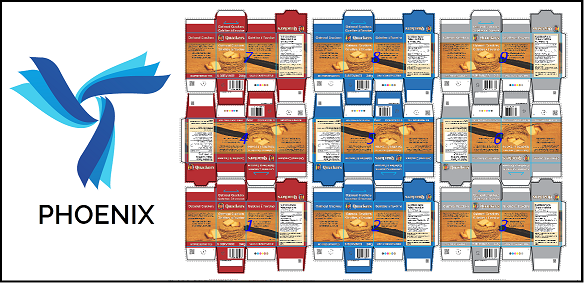

Phoenix

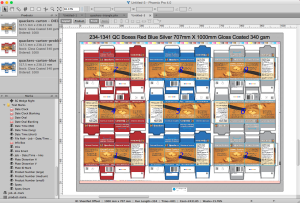

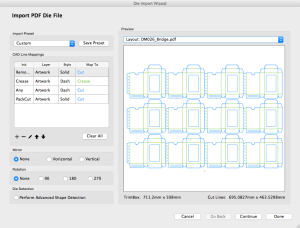

Phoenix is a solution for ganging objects intended for using die cutting for finishing. It will base on the die line to perform calculation on media saving and improves productivity. Similar to Quickfit it will calculate based on the die line of the design and the print quantity to reach the best optimum solution for a printing project. Ganging of jobs do not have to be the identical, it can be in different shapes and different print quantity. This opens up the possibility of print greeting cards and labels.

It is a complete PDF workflow, from artwork coming in and files going out for productions. When a ganging solution is chosen, it will generate a file consist of a PDF ready for printing, a die line file for cutting, and most important of all, a report file indicate which are the jobs make up for this solution and detail of the customers for delivery.

Phoenix is designed to take order information from any front end MIS or ERP, and for the same reason it can tie with MIS or ERP for passing the production information back for further processing.

“Within the first week of our trial we were sold. We were able to create print-ready layouts in Phoenix over three times faster than our existing solution. Since the switch to Phoenix we have been able to simplify our workflow and reduce errors significantly during both pre-press and post-press.”

-Ricardo Reis, Pre-Press Operator

Cartonagem Cardoso, Portugal

IMPOSITION features

- Step and Repeat

- Instant Artwork to Die Alignment

- Group and Resolve Overlaps

- Grid Based Step and repeat

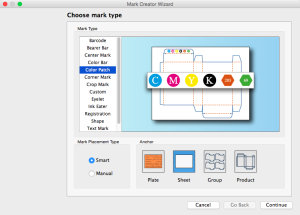

- Powerful Dynamic Marks

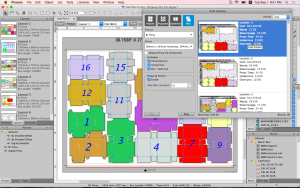

PLANNING benefits

At the heart of Phoenix is a revolutionary ganging engine designed to minimize both press costs and post-press complexity.

- Generate cost-optimal layouts

- Find best sheet/press combos

- True shape tightly nested layouts

- Optimize post-press cutting

- Review cost, waste, time, overruns