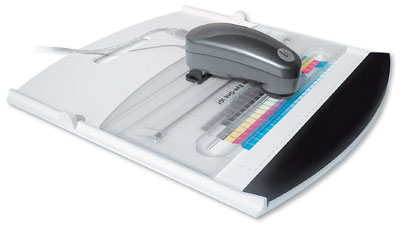

StarProof (1 bit)

Star Proof

When printing color proofs, large format posters or composites that demand top quality color reproduction, choosing a PostScript RIP is as important as choosing the color printer itself. ColorExpress from Compose is the ideal RIP for digital color printing. Based around the high performance Express RIP, ColorExpress offers interfaces for all popular large format inkjet printers and A3+ laser printers.

However, ColorExpress is not just a RIP. With innovative productivity features bundled as standard, an easy-to-use console and powerful color management and screening capabilities, ColorExpress is a comprehensive solution for graphic arts professionals.

Screened Contract proofs produced quickly and economically

Star Proof gives you all the controls you need for faithful reproduction of images on inkjet printers. To maintain image sharpness, Star Proof uses the actual dots of the original RIPped 1-bit data, preserving dot patterns, screening and rosettes on the proof. The results on high quality inkjet printers are stunning and contract-quality proofs. Star Proof color management tools are designed for actual dots proofing to simulate printing press process character to ensure that you produce color proofs that truly match final press sheets. Add in a powerful set of productivity features for managing spot special colors, oversize printing, soft proofing, progressive proofs, simulate misregistration and remote proofing – you have a complete cost-effective solution for today’s demanding proofing needs.

Why halftone Proof?

Contract Proofing on a wide range of affordable Inkjets

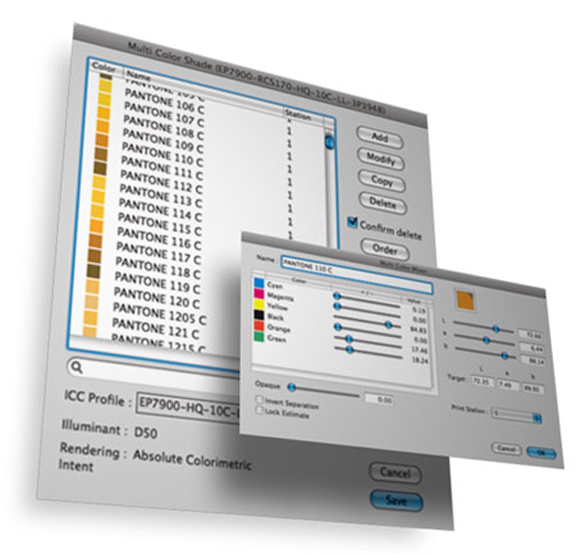

Multi Color Shade

Special colors is most difficult for digital proof to match color because of color gamut limitation on inkjet printer and capable color management software. Now Epson UltraChrome HDR™ Ink utilizing ten colors including an all new orange and green Epson UltraChrome HDR inks produce the widest color gamut ever from an Epson Stylus Pro printer. Star Proof lets you fully utilize advantage of the technology on Multi Color Shade feature to match to any standard special color library, more than 90% high accuracy of the Pantone Solid Coated™ colors.

Print Separation

ICS Certified Proofs

ICS Certified is an optional program for verifying proof quickly and accurately. It can be use with any proofing system to check color quality and consistency of digital proofs. In Europe, the FOGRA Digital Proofing standard is commonly used, where as in other countries, standards such as SWOP (in US), TOYO (in Japan) are common.

ICS Certified allows you to choose an international standard as a reference and define your own company verification color bars.

- Eye-One

- DTP20 Pulse, DTP41, DTP45 and DTP70.

You can generate a control strip for a supported measurement device using either a predefined patch set or a new patch set that you create from scratch. Measurement result can be output as a brief summary printed on a label or as a detail report sheet. This allows you to detect color variations after a certain period of time.

Packaging simulation proofing feature

Star Proof offers new features for packaging applications that able simulate the plate dot characteristics of flexo printing to ensure that your proofs accurately reflect what will be produced on the press.

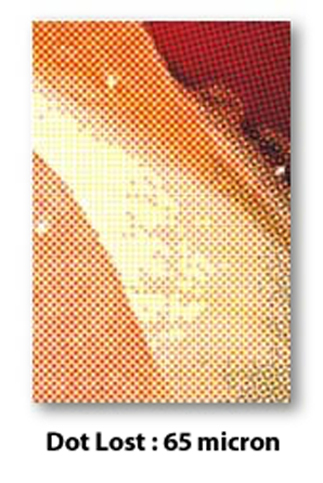

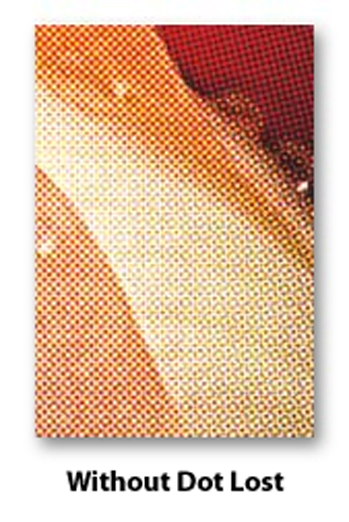

Screening dots prepared for flexo plates are normally adjusted in width or height by a small percentage to compensate for expansion during printing. Star Proof Distortion expands distorted dots to the original size with user controls to correct the size of the screening dots based on the original distortion ratio or the expansion ratio. Star Proof also compensates for the lost of small dots in the transfer to flexo plates during plate making. By entering a Dot Lost size, any screening dots smaller than this size will be removed and will not appear on the proof.

Flexo printing, especially for printing on corrugated media, has extremely high dot gain of up to 15% to 20% and normal dot gain adjustment cannot compensate dot gains of this magnitude. Star Proof’s Extreme Dot Gain increases screening dot size dramatically by adding a border of 1 or more pixels around the screening dot – again, giving you the confidence that what you see on your proof matches the press.

Dot Lost is an option for simulate flexo, letterpress or etc.plate not able to hold some small dots printing result. If input 65 micron in Dot Lost text field those dots smaller than 65 micron will missing on the proof.

Misregistration is an option for simulates the press miss registration per separation, allows you to check if the applied trapping distance covers the press miss registration tolerance to avoid gaps.

Color Shade Estimate option provides spot color auto fine tuning and report to assures consistent color quality by measuring and comparing color values.

Extreme Dot Gain is an option for increase the raster file dot gain. Input number of pixel value in Extreme Dot Gain text field for increase dots and objects border to simulate the plate pressure on printing press.

Star Proof offers new features for packaging applications that able simulate the plate dot characteristics of flexo printing to ensure that your proofs accurately reflect what will be produced on the press.

Screening dots prepared for flexo plates are normally adjusted in width or height by a small percentage to compensate for expansion during printing. Star Proof Distortion expands distorted dots to the original size with user controls to correct the size of the screening dots based on the original distortion ratio or the expansion ratio. Star Proof also compensates for the lost of small dots in the transfer to flexo plates during plate making. By entering a Dot Lost size, any screening dots smaller than this size will be removed and will not appear on the proof.

Flexo printing, especially for printing on corrugated media, has extremely high dot gain of up to 15% to 20% and normal dot gain adjustment cannot compensate dot gains of this magnitude. Star Proof’s Extreme Dot Gain increases screening dot size dramatically by adding a border of 1 or more pixels around the screening dot – again, giving you the confidence that what you see on your proof matches the press.

Invert Separation option is to invert any special separation. It is very useful to simulate white color reverse printing on transparency media result. Normal ink jet printer not able to print white ink but this feature allow to invert white separation channel to print gray as transparent area.

Isi Calibration to simulate Printing press Process

Star Proof’s Isi Calibration System (ICS) gives you a comprehensive set of tools to achieve excellent color matching between proof and press, offering traditional color calibration and fine controls for matching inks via color shade, calibration curve and dot gain compensation. And with superb reproduction of blacks and grays, and options for handling UCR and GCR, you can easily achieve quality levels that are difficult for many systems based on ICC profiling.

At the heart of ICS is a straightforward process and powerful for color calibration – one which is intuitive to press operators. ICS uses spectrophotometer readings to analyze and compare printing press target charts and proof printer calibration charts. The readings are input to Star Proof which then creates a system profile for the specific press and saves this for future use.

Save time with ICS’s automated calibration

You can save calibration time by using ICS’s auto-calibration for automated reading of color patches with the X-Rite DTP-41 or EyeOne. ICS’s auto calibration takes the device measurements and prepares a color curve with the appropriate gamut which you can then fine tune for even more precise color matching.

ISI Calibration –ICC

Star Proof implemented ICC profile on top of ICS color management technology to remain all advantages of ICS. This feature allows users to import standard press ICC profiles. In addition, the user has tools that allow the creation of their own custom ICC profiles that produce great visual results with low Delta E value. Users can view Lab and CMYK value and apply flexible color adjustment, set maximum total ink for printing and import spot color Lab value from spectrophotometer devices.

Controlling shadow areas with Ink Turner

In areas of the proof where overlaps between C, M, Y and Black are shown, Ink Tuner lets you adjust the color densities of individual inks and control shadow areas and view actual ink values in real time. Ink Tuner automatically manages the process of adjusting ink levels to ensure ink hues are unaffected which gives a robust system to control both color and density in selected areas – a process not possible with many ICC color management system.

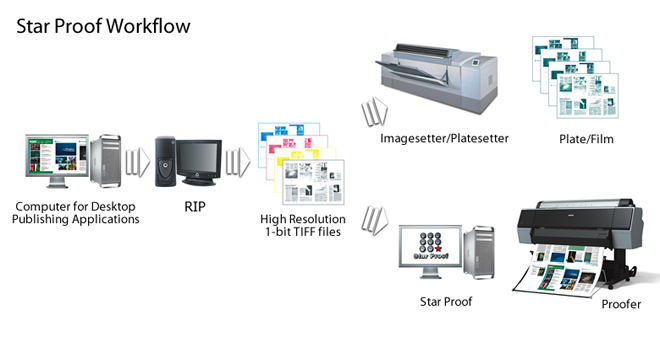

Proof from almost any RIP

Star Proof uses compressed 1-bit TIFF separations as source data to create proofs so you can use Star Proof with almost any PostScript/PDF RIP.

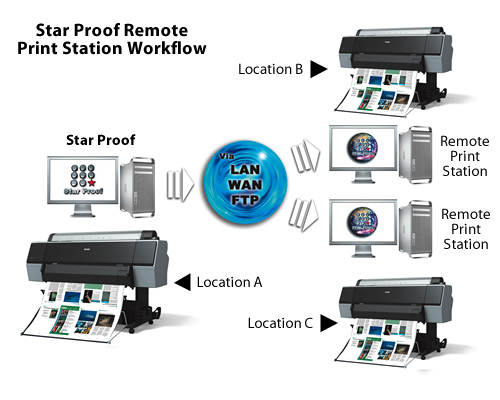

Efficient remote proofing for faster Approvals

Star Proof Remote Print Station gives print companies a cost effective solution to providing customers with the capability to print contract proofs locally on inkjet printers in their own offices – shortening approval cycles and improving the service to your customers. Using an ftp server running under Mac OS X, Remote Print Station takes color corrected proofs over the Internet from the print company’s master Star Proof station and controls output to the local printer. Files can be compressed for transmission and then decompressed at the remote print site. With a Remote Print Station to control each printer, Star Proof is also capable of proofing simultaneously on multiple printers which may be sited locally or remotely – enhancing throughput and increasing flexibility of workflow.